Concentrating Solar Power

Concentrating solar power (CSP) plants use mirrors to concentrate the sun's energy to drive traditional steam turbines or engines that create electricity. The thermal energy concentrated in a CSP plant can be stored and used to produce electricity when it is needed, day or night. Today, roughly 1,815 megawatts (MWac) of CSP plants are in operation in the United States.

Parabolic Trough

Parabolic trough systems use curved mirrors to focus the sun’s energy onto a receiver tube that runs down the center of a trough. In the receiver tube, a high-temperature heat transfer fluid (such as a synthetic oil) absorbs the sun’s energy, reaching temperatures of 750°F or higher, and passes through a heat exchanger to heat water and produce steam. The steam drives a conventional steam turbine power system to generate electricity. A typical solar collector field contains hundreds of parallel rows of troughs connected as a series of loops, which are placed on a north-south axis so the troughs can track the sun from east to west. Individual collector modules are typically 15-20 feet tall and 300-450 feet long.

Compact Linear Fresnel Reflector

CLFR uses the principles of curved-mirror trough systems, but with long parallel rows of lower-cost flat mirrors. These modular reflectors focus the sun's energy onto elevated receivers, which consist of a system of tubes through which water flows. The concentrated sunlight boils the water, generating high-pressure steam for direct use in power generation and industrial steam applications.

Power Tower

Power tower systems use a central receiver system, which allows for higher operating temperatures and thus greater efficiencies. Computer-controlled mirrors (called heliostats) track the sun along two axes and focus solar energy on a receiver at the top of a high tower. The focused energy is used to heat a transfer fluid (over 1,000° F) to produce steam and run a central power generator. Energy storage can be easily and efficiently incorporated into these projects, allowing for 24 hour power generation.

Dish-Engine

Mirrors are distributed over a parabolic dish surface to concentrate sunlight on a receiver fixed at the focal point. In contrast to other CSP technologies that employ steam to create electricity via a turbine, a dish-engine system uses a working fluid such as hydrogen that is heated up to 1,200° F in the receiver to drive an engine. Each dish rotates along two axes to track the sun.

Key Requirements for Concentrating Solar Power Plants

-

Financing – The primary challenge for any utility-scale energy generating facility, including CSP, is project financing.

-

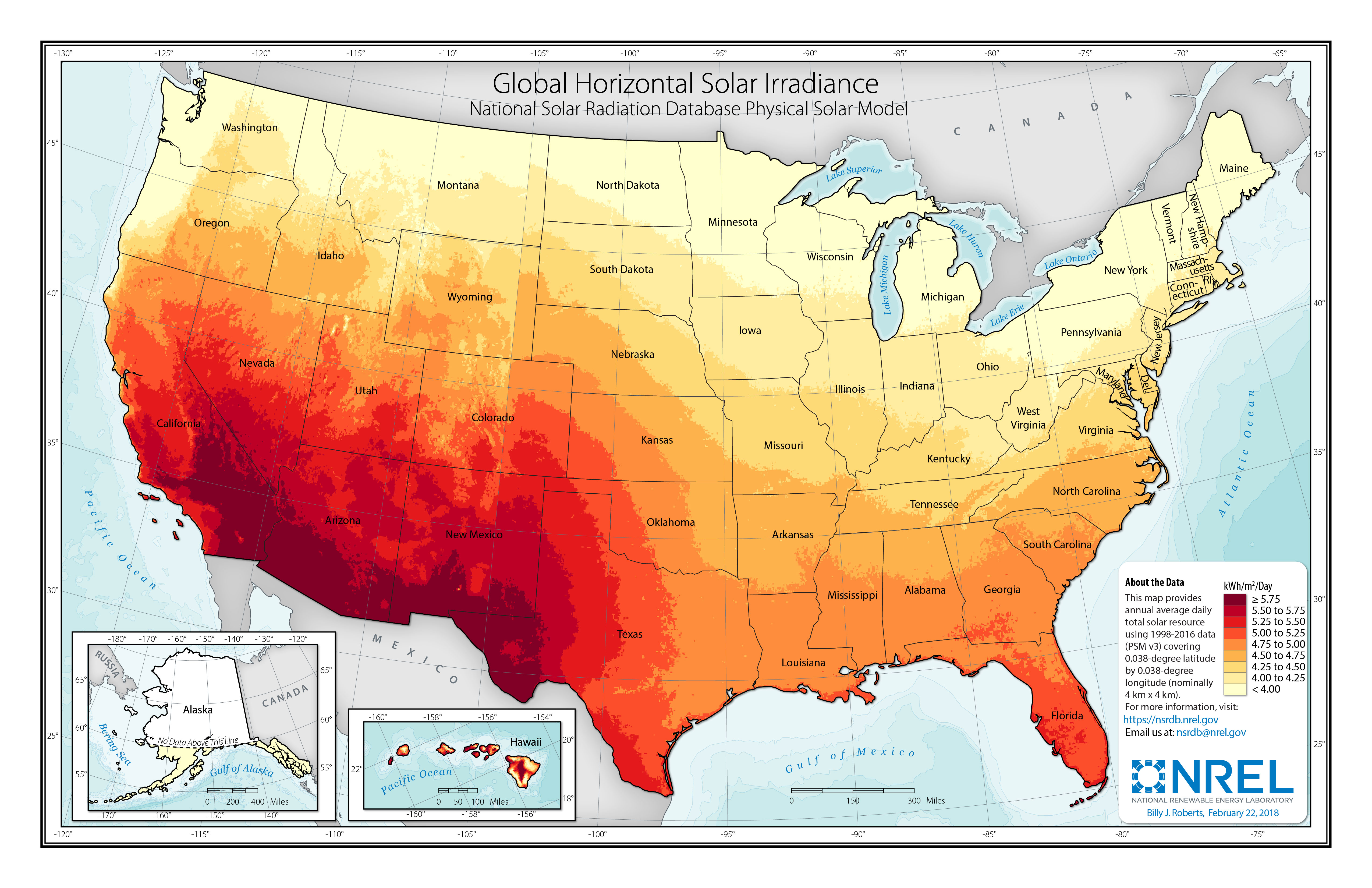

Areas of high solar radiation – In order to concentrate the sun’s energy, it must not be too diffuse. This is measured by the direct normal intensity (DNI) of the sun’s energy. Production potential in the U.S. Southwest stands apart from the rest of the U.S., as the map from the National Renewable Energy Laboratory below demonstrates.

-

Contiguous parcels of land with limited cloud cover – A CSP plant operates most efficiently, and thus most cost-effectively, when built in sizes of 100 MW and higher. While land needs will vary by technology, a typical CSP plant requires 5 to 10 acres of land per MW of capacity. The larger acreage accommodates thermal energy storage.

-

Access to water resources – Like other thermal power plants, such as natural gas, coal and nuclear, most CSP systems require access to water for cooling. All require small amounts of water to wash collection and mirror surfaces. CSP plants can utilize wet, dry, and hybrid cooling techniques to maximize efficiency in electricity generation and water conservation.

-

Available and proximate transmission access – CSP plants must be sited on land suitable for power generation with adequate access to an increasingly stressed and outdated transmission grid. Access to high-voltage transmission lines is key for the development of utility-scale solar power projects to move electricity from the solar plant to end users. Much of the existing transmission infrastructure in the Southwest is at full capacity and new transmission is urgently needed.

CSP plants in the United States

For more information, visit the NREL Concentrating Solar Power Projects page.

Ivanpah Solar Electric Generating System (Brightsource Energy/NRG Energy, Inc.)

Located across 3,500 acres of federal land in California’s Mojave Desert, the Ivanpah facility is a 392-megawatt solar generation plant consisting of 173,500 heliostats and three power towers with the capacity to provide clean, sustainable power to over 100,000 American homes. Developed through a partnership among BrightSource Energy, NRG energy, and Google, and constructed by Bechtel, the Ivanpah project has created more than 1,000 construction jobs since commencing construction in October of 2010.

Mojave Solar One (Abengoa Solar, Inc.)

Located across 1,765 acres about 100 miles northeast of Los Angeles, the 280-megawatt gross parabolic trough plant will be capable of powering approximately 90,000 American households. Developed by Abengoa Solar Inc., the Mohave Project has created approximately 830 American jobs and will continue to employ 70 once completed.

Solana (Abengoa Solar, Inc.)

The 250-megawatt Solana parabolic trough plant near Gila Bend, Arizona uses thermal storage technologies, and provides clean, reliable power to more than 97,000 Arizona Public Service customers. Developed by Abengoa Solar, the project created 1,700 construction jobs and was placed in service October 2013.

Crescent Dunes (SolarReserve, LLC)

The Crescent Dunes project near Tonopah, Nevada is a 110-megawatt solar generation plant with 10 hours of full load storage that enables on-demand energy production day and night. It is the nation’s first commercial-scale Molten Salt Power Tower facility with energy storage and has no requirements for natural gas back up. With a 640-foot power tower and 10,347 heliostats, the Crescent Dunes project powers 75,000 American homes. Developed by SolarReserve and constructed by ACS Cobra, this 1,600-acre project has created approximately 4,300 direct, indirect, and induced jobs.

Genesis Solar (NextEra Energy Sources, LLC)

Located in Blythe, California, the Genesis solar energy project is a 250-megawatt solar generation plant that consists of more than 600,000 parabolic mirrors across 1,800 acres. The plant has the capacity to power approximately 88,000 American homes. Developed by NextEra Energy Sources in collaboration with Sener and Fluor, the project was placed in service in April 2014, and created 800 construction jobs.

Solar Energy Generating System (NextEra Energy Sources, LLC)

With a combined capacity of 354-megawatts from three separate locations at Harpet Lake, Kramer Junction, and Dagget in Californa, the SEGS plants provide clean, sustainable power to 232,500 American homes.

Nevada Solar One (Acciona)

In collaboration with Nevada Power Company and Sierra Pacific Resources, the Nevada Solar One project covers 400 acres and has a capacity of 64 MW. The plant consists of over 182,000 mirrors and has 760 parabolic concentrators. It has created in excess of 800 construction jobs and currently employs over 30 people in permanent operational positions. Every year, Nevada Solar One generates enough electricity to power 14,000 Nevada homes.

Kimberlina Solar Thermal Power Plant (Areva)

Located in Bakersfield, California the Kimberlina plant, formerly owned and operated by Ausra, now operates under AREVA Solar. At 5 MW capacity, this 10 acre project is the second of its kind to be completed in California, with the first put in service twenty years prior.

Sierra SunTower (eSolar)

In the process of developing the Sierra SunTower in Lancaster, California from start to finish, eSolar created more than 250 construction jobs and currently provides 6 full-time, permanent positions. At 5MW, the SunTower powers more than 4,000 California homes annually and offsets over 7,000 tons of CO2.

Martin Next Generation Solar Energy Center (FL Power & Light)

Spanning 500 acres and through the use of over 190,000 mirrors, the Martin NextGen Solar Energy Center in Indiantown, Florida has a 75 MW generation capacity. This facility is the first solar and natural gas co-generation facility in the world. The 155,000 MWh each year can power over 11,000 homes.

Stillwater Solar Geothermal Hybrid Project (Enel Green Power)

As Enel Green Power's first solar project, the Stillwater plant uses 240 acres and more than 89,000 polysilicon PV panels for the solar capabilities of this cogeneration plant. Capable of producing 2 MW in solar alone, this first of its kind combined solar and geothermal plant has an overall capacity of 26 MW. Located in Fallon, Nevada the Enel Green Power facility generates enough energy to power 15,000 homes.